Below if a overview of the most common types of pallets used in shipping across the world today.

Pallets (also known as skids) are flat transport structures that support goods while being lifted by forklifts, pallet jacks, front loaders, jacking devices, or cranes. Pallets provide structural support for unit loads, making handling and storage easier.

A pallet is typically used to transport goods in shipping containers, which are wrapped with stretch wrap, shrink wrap, or strapping. Due to its ease of use with modern packaging, such as corrugated boxes and intermodal containers commonly used for bulk shipping, it has dramatically replaced older forms of crating like wooden boxes and barrels.

While wooden pallets are the most popular other recycled materials such as plastic, metal, and paper can also be used as pallets.

Due to wide range shipping container use, pallets have become more popular because of containerization for transport. There are many pallets that can handle loads up to 2,000 lbs per skid. The United States alone will make about half a billion pallets in 2022, and it will use about two billion pallets.

Stacks of heavy items can be moved easier with pallets. There are several different kinds of forklift trucks that can haul pallet loads, as well as hand-pumped and hand-drawn pallet jacks. In order to utilize pallets economically, it is necessary to construct commercial or industrial buildings. It is more convenient to handle items if they can pass through standard doors and buildings.

This is why most modern pallet standards, such as the euro pallet (800 mm x 1,200 mm) and the US military 35 in x 45.5 in (890 mm x 1,160 mm), are designed to fit through standard doorways.

Pallets can significantly reduce handling and storage costs for businesses that use them, and they can also move materials much faster than those that don’t. It is an exception for establishments that move small items, such as jewelry, or large ones, such as trucks or industrial containers.

There is no single international standard for pallets, which makes international trade extremely expensive. It is difficult to establish a single standard due to the variety of needs it would have to meet: fitting through doorways, fitting in standard containers, and bringing low labor costs. When an organization already handles large pallets, it may not be worthwhile to pay the higher handling cost of a smaller pallet that will fit through a door.

Pallet pooling and recyycling is becoming more and more popular due to costs and the need to focus on core business. Users can receive reusable pallets from some pallet suppliers, which sometimes include tracking devices. Pallets can be supplied, cleaned, repaired, and repurposed by pallet management companies.

Heavy-duty pallets can be reused multiple times and are a form of reusable packaging. Pallets that are lightweight are designed to be used only once. According to EU law, packaging items should be reused rather than recycled or discarded.

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur arcu erat, accumsan id imperdiet et, porttitor at sem. Nulla quis lorem ut libero malesuada feugiat. Lorem ipsum dolor sit

Most wooden pallets are constructed of 3 or 4 stringers that support several deckboards upon which items are placed. The first number in a pallet measurement is the stringer length, and the second number is the deckboard length. Pallets that are square or nearly square help prevent a load from tipping over.

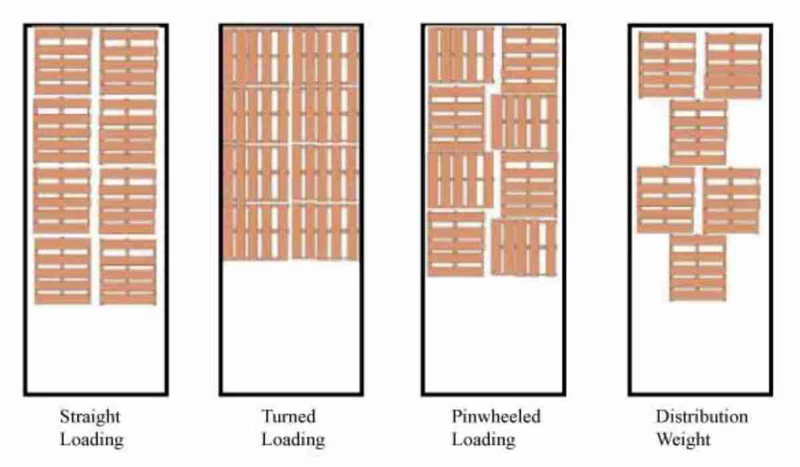

To be accessible to forklifts and pallet jacks, pallets must pass through buildings easily, stack in racks easily, and work in automated warehouses. It is also recommended that pallets are packed tightly inside intermodal containers and vans in order to avoid shipping by air.

Pallet dimensions do not have universally accepted standards, despite the existence of some common standard sizes. Hundreds of pallet sizes are used worldwide by companies and organizations. [2] While no single dimensional standard governs pallet production, a few sizes are widespread.

North American pallets of 48×40 inches are called GMA pallets, and they have stringers measuring 48 inches and deckboards measuring 40 inches. They were standardized by the Grocery Manufacturers Association (GMA).

Depending on the type of pallet, a standard wooden pallet (48 inches by 40 inches by 6 inches or 1,219mm by 1,016mm by 152mm) may weigh between 33 pounds and 48 pounds (15 kg to 22 kg).

It is typical for GMA pallets to weigh 37 pounds (17 kg), and to measure 6+1⁄2 inches (170 mm) tall. There are three and one-quarter inches (83 mm) of width and five and sixteen inches (7.9 mm) thick in each of the deck boards. The weight capacity of pallets of other dimensions varies.

Mauris blandit aliquet elit, eget tincidunt nibh pulvinar a. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Donec velit neque, auctor sit amet aliquam vel, ullamcorper sit amet ligula. Pellentesque in ipsum id orci porta dapibus. Curabitur aliquet quam id dui posuere blandit. Mauris bla

The International Organization for Standardization (ISO) reviewed and confirmed six pallet dimensions: